qzhr@chinaqiangzhen.com

+86 0553-8768222

qzhr@chinaqiangzhen.com

+86 0553-8768222

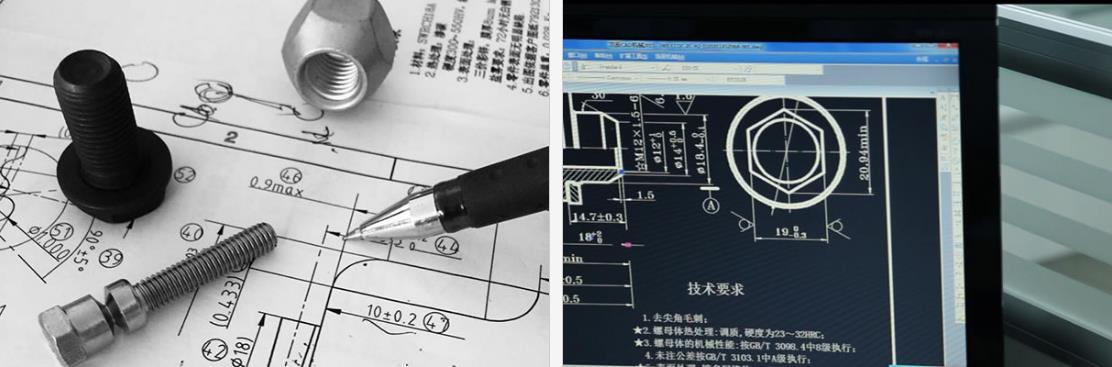

Customizing and Co-developing Fasteners for You

We mainly provide customizing and co-developing fasteners for car makers and auto parts both in domestic and overseas markets. We can produce customized parts according to your drawings, samples or your requirements, and especially good at cooperating on the development of non-standard parts according to your time node. Since 2006 we become the tie one supplier for car makers, we have developed thousands of high strength and high precision fasteners applied in engines, chassis, wheel nut and other system.

Strict Control of Delivery Time

We adopt ERP system to control the management of sales, planning and production. The planning team will prepare the materials and arrange production, production department will be responsible for the production according to the time schedules. They work tightly to ensure a just-in-time delivery.

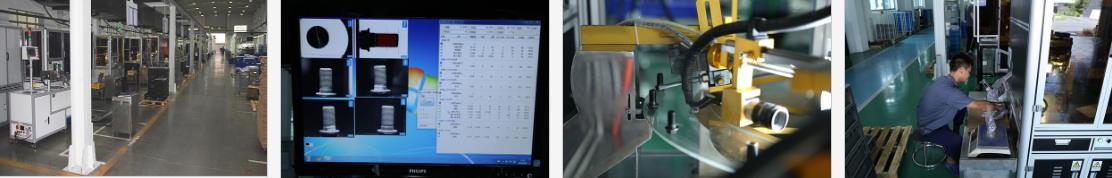

Complete Processing Foundation

We equip with all the related procedures in making a fastener, starting from cold/hot forging, machining, thread forming, heat treatment, and surface treatment, meanwhile, optical automatic selection machine can realize full automatically inspection the parts before parts packing.

Cold/Hot Forging - Parts Forming

We have 33 sets of multi-station cold forging machines, Processing sizes BTW ø4-20mm, Length: 5-220mm, able to produce from three die three punching, four die four to six die six punching processing deformation. Daily output of 60 tons. Meanwhile, we have 3 set of hot forging machine, avaliable sizes btw 8-30mmX 20-300mm, daily output: 6 tons.

CNC Machining-Refined Machining Ability

We have 59 sets of CNC machining equipment, grinder’s accuracy control at 4 microns. Daily output in 400 thousand pieces.

Threading

We have 54 sets of threading equipment, processing sizes at ø M4-20, length BTW 5-220mm. Daily output 3,000,000PCS.

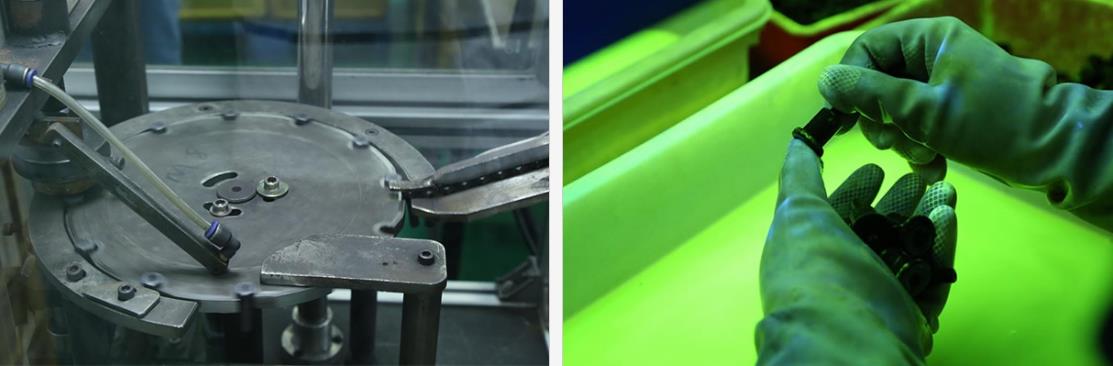

Heat Treatment: Insurance of Mechanical Properties

Heat treatment is a key step in the fastener processing. The advance level of the equipment directly affects the final quality of the products. Our heat treat treatment is using Korea DONGAM continuous bright carburizing quenching furnace, which adopting methanol cracking atmosphere protection and using propane to adjust the carbon potential. All autonomic control and monitor the whole process including, inlet, heating temperature, heating time, carbon potential, running speed, etc. All the date can be auto saved. Hence the quality of the heat treatment can be ensured. Daily output reaches 40 tons.

After heat treatment, we will carry out magnetic crack detection, meanwhile, meanwhile further laboratory tests such as tensile strength, yield strength, metallographic microstructure, surface hardness, wedge load intensity, proof load and fatigue test , which is to ensure the parts meet the strength grade and avoid plastic deformation and fatigue fracture under the action of alternate load.

Surface Treatment

We have surface treatment automatic facilities of phosphating, oxidation, sealant, zinc aluminum coating and varous types of plating.

Zinc Aluminum Coating

Zinc aluminum coating, also called environment friendly Dacromet, it is chromium free, a new green coating. Its anti-corrosion ability is much higher than Dacromet, and can endure NSS salty spray test up to 1000 hours. Atotech is our chemical supplier.

Plating

We have introduced fully automatic plating lines including racking and barrel plating, the chemical supplier is Mac Dermind. The type of plating will be zinc, zinc-nickel ,Zinc Iron and nickel-chromium alloy as well as trivalent chromium passivation, de-hydrogen and sealing of the passivation.

Cleanliness Control

In order to ensure the customized products meet the requirements of different cleanliness, our company is equipped with a complete set of production and testing equipment from cleaning, inspection, to packaging. Among them, the cleaning machine is PORFU Hydrocarbon Cleaner, and drying and packaging is within a 100,000-grade food-grade cleaning room. The cleanliness detection uses ultrasonic cleaning, weighing and drying. Final detection is using JOMESA microscopy to analyze the amount of metal and non-metal particles.

Appearance 100% Inspection

Before packaging, the parts will be inspected via automatic appearance defect screening machine, which can achieve 360 degree inspection of one part. The selecting speed can reach 200 PCS per minute.

Delivery

Qualified products will be packed as per order. Our product label is QZ, our brand name is Qiangzhen.

Mobile

Wuhu qiangzhen automobile Fastener Co., Ltd. all rights reserved 皖ICP备17001298号-1 皖公网安备 34022102000423号 technical support:whtime.net